Smart shielding wall relieves care providers of time-consuming and complicated cleaning protocols

The shortages of personal protective equipment are increasing the pressure on the healthcare system in the fight against COVID-19. In collaboration with Pieter van der Staay, FLEX/design, Delmic, Star-shl diagnostic centers and Scala Scientific, a team of TU Delft students have developed a smart shielding wall that relieves care providers of time-consuming and complicated cleaning protocols. The mobile testing facility offers the possibility of in-home diagnostics that could help general practitioners to give the right medical advice. In three weeks’ time, the students developed a prototype, at the request of Pieter van der Staay, a general practitioner.

“Since the outbreak of COVID-19, patients with suspicious complaints have been reporting to my surgery several times each day. Following triage by telephone, I want to do a few more supplementary tests on the patient, like blood-oxygen level, respiration and temperature—all of which are possible indicators of coronavirus. The patient comes in through a special entrance, I’m covered in protective clothing from head to toe and, after the examination, the entire examination room has to be disinfected,” explains the general practitioner from Hoogvliet. “For patients who are not able to come to the practice, I make house calls in this special clothing. This is a time-consuming and convoluted way of working, for which this group of TU Delft students have developed a solution.”

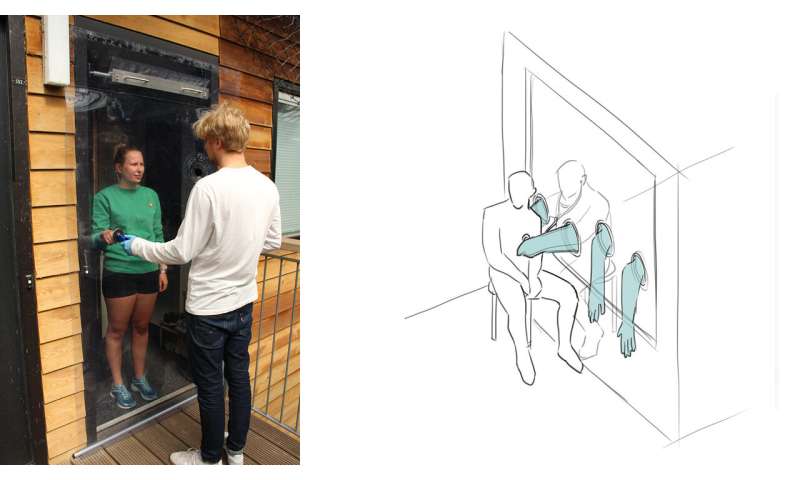

The students started working on Van der Staay’s request and devised a smart shielding wall that ensures that the patient does not come into contact with the care provider. The students are working on two different models of this shielding wall. The MediTent makes it possible to create a temporary testing area at a given location, and the MediScreen relocates the testing area to the front door of an immobile patient. The design allows care providers to give medical advice based on medical tests without the use of scarce protective equipment.

General practitioner Van der Staay and the students share the common goal of helping care providers do their jobs as well as possible while limiting the use of scarce protective equipment, in order to avoid any additional pressure on the healthcare system. The first prototype has now been completed and tested, in collaboration with FLEX/design and Delmic. Additional tests will be performed in the coming weeks in order to improve the MediScreen prototype, and a pilot project will be launched in collaboration with the Star-shl diagnostic centers. The team hope to deliver the first smart shielding walls within three weeks and to have production set up, in collaboration with Scala Scientific.

Source: Read Full Article